|

* The options can be modified by referring to the customer requirements.

|

This machine is designed to be inserted in the opposite direction, unlike the original direction of Liner seal.

Liner seal can be inserted in the opposite direction, depending on the user's purpose.

Because the Liner seal is cut and inserted at the same time, the user is easy to operate the system by using the PLC touch screen.

It can be manufactured regardless of shape or size,

and it was recently manufactured in flip top cap.

Our Cap Lining Machines place hermetic seals into caps by means of liner coils or pre-cut liners.

OPPOSITE DIRECTION

INSERTING MACHINE

CAPACITY 300~400 pcs / min

ELECTRICITY kw

DIMENSION mm

WEIGHT kg

|

|

* The options can be modified by referring to the customer requirements.

|

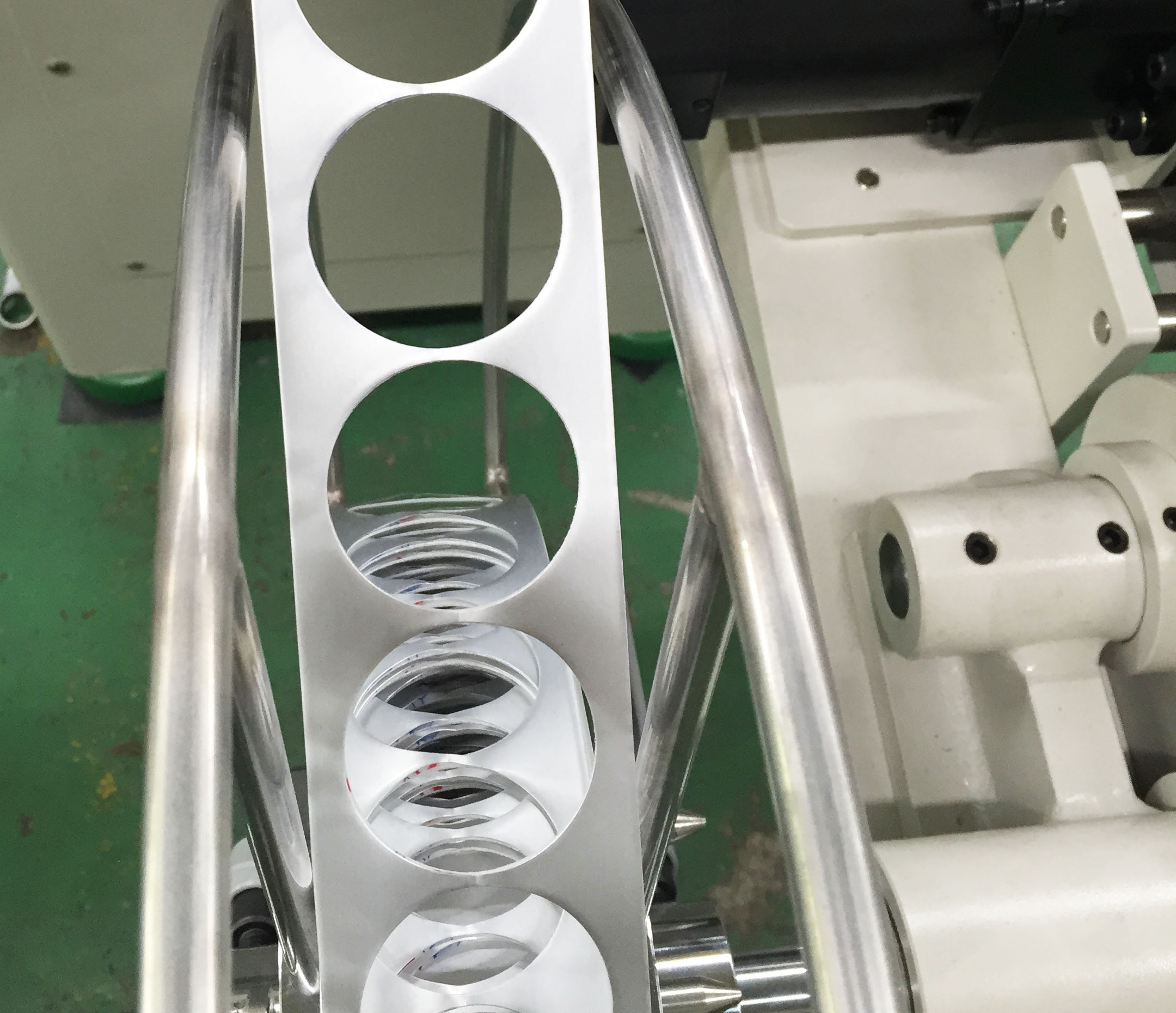

This machine is the inserting machine, which is equipped with two seal feeder.

Two seal of different uses are inserted simultaneously into one cap, and the user can be controlled via an automatic control system.

Using this machine, customers can insert seals quick and accurate insertion into the cap.

JOONGSAN designs and manufactures Cap Lining Machines for punching liner discs from the supply and placing them into the caps, at speeds up to 450 caps

per minute, depending on the cap size and design.

JOONGSAN has tools designed for cutting and placing various types of disc configurations, with machines of up to 6 punches.

W-TYPE LINER

INSERTING MACHINE

CAPACITY 400~450 pcs / min

ELECTRICITY 0.8 kw

DIMENSION L2,200 x W2,250 x H1,300 mm

WEIGHT 950 kg

|

|

* The options can be modified by referring to the customer requirements.

|

This machine is designed to insert a liner seal into the plastic cap.

Warm-up, preparation, finish selection, coating, and cleaning are fully automated and controlled through the user-friendly touch screen.

1. Scope of Application:

The cap lining machine can automatically inserts to the cap

liner into the bottle cap (the liner in pieces)

This machine is widely used in the industry :

- Pharmaceutical industry - Cosmetics industry

- Food industry - Liquor industry

- Lube industry

2.Applicable liner material:

paper or pulp board liner, aluminum foil liner, and foam liner

The cap liner is cut in pieces inadvance

(Precut liner)

PLASTIC CAP LINER

INSERTING MACHINE

CAPACITY 300~400 pcs / min

ELECTRICITY kw

DIMENSION mm

WEIGHT kg

|

|

* The options can be modified by referring to the customer requirements.

|

This machine is a gasket seal inserting machine.

It can replace various type of seals to fit the cap size because it can replace a changing parts.

This machine is equipped with a special device, so you can replace 8 different sizes of seal.

GASKET SEAL

INSERTING MACHINE

CAPACITY 300~400 pcs / min

ELECTRICITY kw

DIMENSION mm

WEIGHT kg

|

|

* The options can be modified by referring to the customer requirements.

|

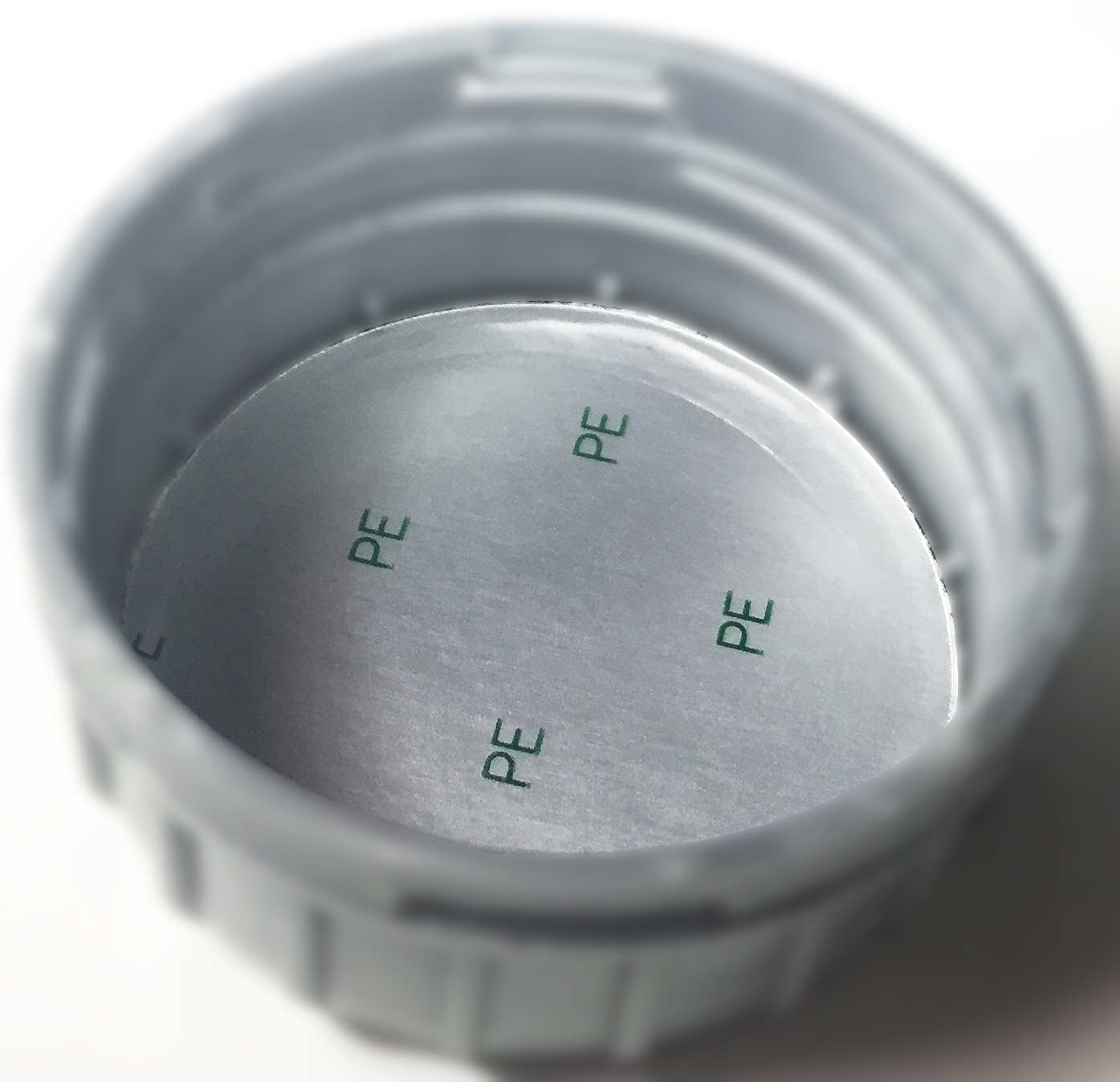

This liner machine is designed for inserting products to the TANK by using a vibration method. This is equipped with two sensors on the entrance and outer part of the machine, which can detects if there has not been a LINER inserted. The speed can be controlled by automatic controller system.

Applicable Scope:

This machine is an ideal liner inserting machine which is widely applied in cap factories,

liner factories, pharmaceutical factories, food products factories, daily chemical factories, packing factories.

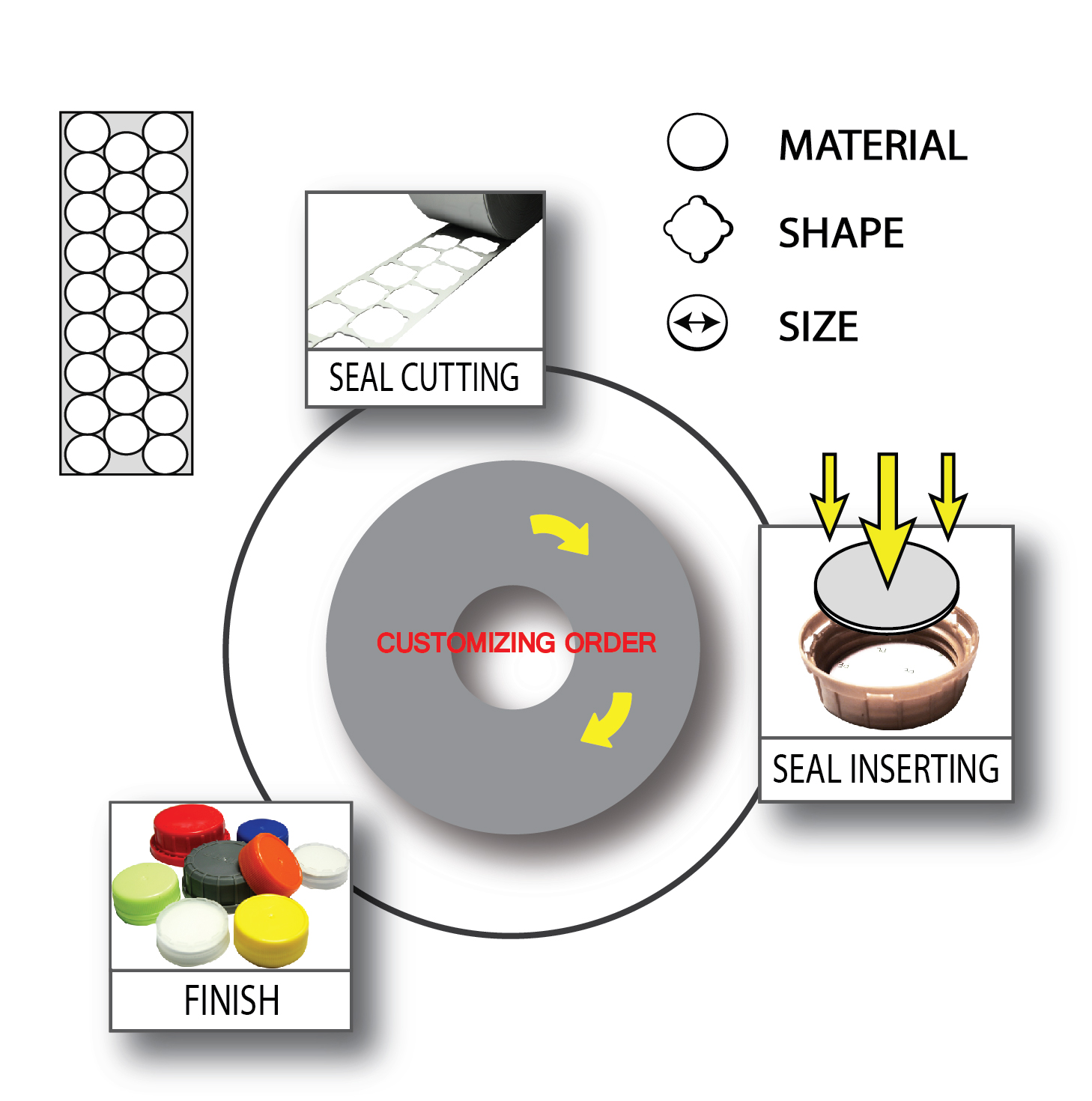

Operation principle: cut the reeled liner materials into specified size and simultaneously insert the precut liner into the cap; finally, the liner pressing unit press the liner to the bottom of the cap.

2 HEAD P.E LINER

INSERTING MACHINE

CAPACITY 400~450 pcs / min

ELECTRICITY 0.8 kw

DIMENSION L2,200 x W2,250 x H1,300 mm

WEIGHT 950 kg

|

|

* The options can be modified by referring to the customer requirements.

|

This machine is a pourer inserting machine.

Pourer is primarily a cap used for liquids such as oils.

This rotary type machine is an automatic production line. The layout of this machine is able to produce one item in large quantities, and be manufactured to control easily, precise and sanitary.

A Pourer insert is a 2 part pre-assemble made of HDPE that is inserted into a shell of a closures and retained by the retaining ring. A special bottle neck finish is

required to retain the pourer during application.

ROTARY TYPE POURER

INSERTING MACHINE

CAPACITY 300~350 pcs / min

ELECTRICITY 3 kw

DIMENSION L5,800 x W1,800 x H2,800 mm

WEIGHT 2,000 kg

|

|

* The options can be modified by referring to the customer requirements.

|

This machine is a pourer inserting machine.

Pourer is primarily a cap used for liquids such as oils.

This rotary type machine is an automatic production line. The layout of this machine is able to produce one item in large quantities, and be manufactured to control easily, precise and sanitary.

A Pourer insert is a 2 part pre-assemble made of HDPE that is inserted into a shell of a closures and retained by the retaining ring. A special bottle neck finish is

required to retain the pourer during application.

The new version of the Pourer inserting machine is equipped with a dust collector and blower for perfect dust removal.

NEW ROTARY POURER

INSERTING MACHINE

CAPACITY 100~150 pcs / min

ELECTRICITY 1 kwx 4P

DIMENSION L4,700 x W2,800 x H1,700 mm

WEIGHT 3,100 kg

|

|

* The options can be modified by referring to the customer requirements.

|

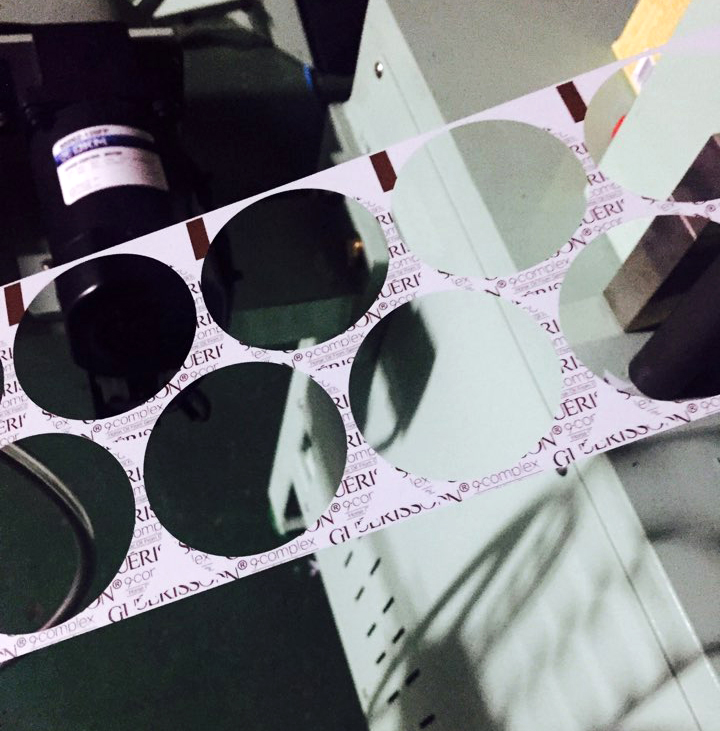

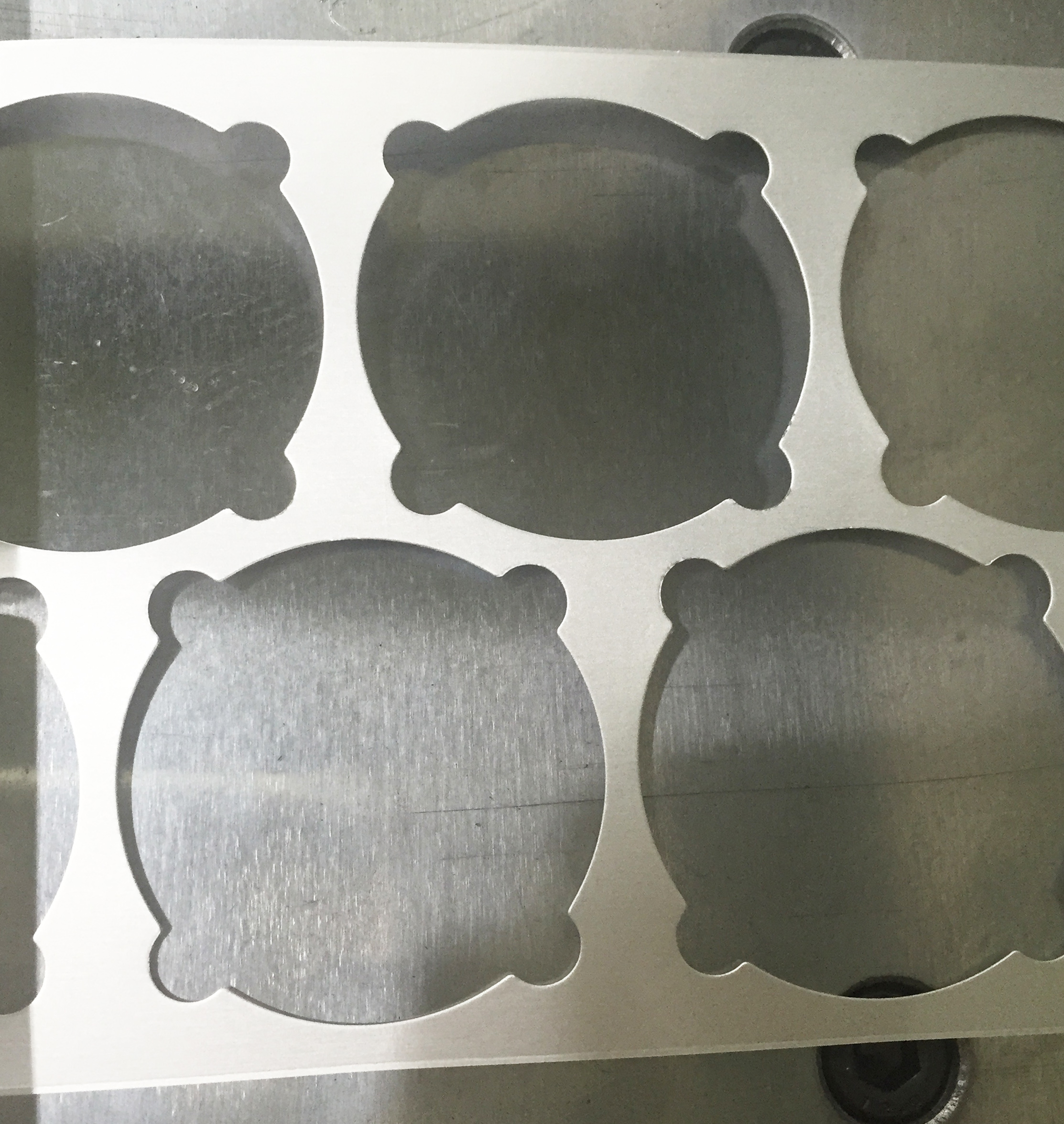

This machine is a Liner seal punching machine which can punching liner roll into liner sheet as the size you need, it can make many size in one machine by changing die cutting mold, and the pieces liners are collected into tubes automatic, no need to collect by worker any more.

Using this automatic machine, customers can easily punching the seals.

The machine has small size, low power (main motor 0.75kw), high efficiency to punch the liner, foil

and so on.

All of our machines can be manufactured to meet the needs and situations of our customers.

Currently, we offer several different models of Cap Lining Machines to suit different production goals.

LINER SEAL

PUNCHING MACHINE

CAPACITY 300~400 pcs / min

ELECTRICITY kw

DIMENSION mm

WEIGHT kg

|

|

| |

|

|

|

Features Specification

MATERIAL

Paper Aluminum Sponge

|

| |

| |

|

|

Products Category

| |

|

|

| |

|

|

|

All machines, which we produce, are engineered so that they work

under automatic working regime.

At the beginning (input) they automatically take and fill up the

cap with particular or selected liner and at the end (output) they control the

suitability of products and eliminate the unsuitable one.

The machine also automatically count and warn to the operator on

all changes trough working period including with signals of short of

packaging or packing material.

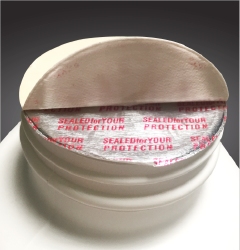

Benefits – What are the benefits of induction sealing?

Induction sealing has many benefits such as:

- Extends shelf life by giving products long-lasting freshness

- Prevents leaking and therefore reduces complaints from the end-user

- Reduces packaging weight

- Protection from counterfeiting and tampering

- Increased productivity compared to other methods of sealing

such as conduction

|

| |

| |

|

Products Gallery

1. Automatic liner cutting and inserting have replaced manual work, which

substantially raises the work efficiency.

2. Liner inserting features good accuracy, high speed and high efficiency;

the bottom is smooth when the liner is stamped into the cap without

upwarp; Finished products have good appearance

and

standardized quality.

3. The machine will stop automatically when there is no material feeding:

the machine alarms and stops automatically when there is no cap

on the cap conveyor belt or when there is no reeled liner material.

4. The machine has automatic count function.

The machine can stop

automatically according to the set number of caps, or an outlet direction

converter of conveyor belt can be equipped; when the number of caps

reaches that set by the user, the converter will automatically convert the

outlet to another box.

5. The operation of the machine is controlled by imported PLC, with

touch screen operation and people-oriented design.

All functions can be

operated and set on the touch screen, simple and convenient.

6. The material conveying length can be adjusted as the liner adopts reeled

raw material.

Adjustment based on different liner materials can save

the material. When the material is conveyed to the cutting and inserting

mechanism of the machine, liner cutting and inserting at the same time,

and the liner will be inserted to the cap on a one-off basis.

7. Through our company's independent research and development,

the whole machine is designed with mechanical transmission,

and parts have applied pneumatic accessories.

The design of

automatic lubrication system guarantees stable operation of

the machine and prolongs its service life.

8. When caps are of different sizes, the replacement of liner

stamping mould, turn plate is simple and convenient.

9. The machine is an automatic packaging device designed and

manufactured by our factory in strict accordance with national GMP

standard and technological requirements.

Our safe and sanitary products can avoid secondary pollution of

materials and omit the sterilization process, especially suitable for occasions with strict sanitary requirements.

Customers can select multiple types of seals depending on their intended use.

Products Description

|